Cam İşleme Makineleri

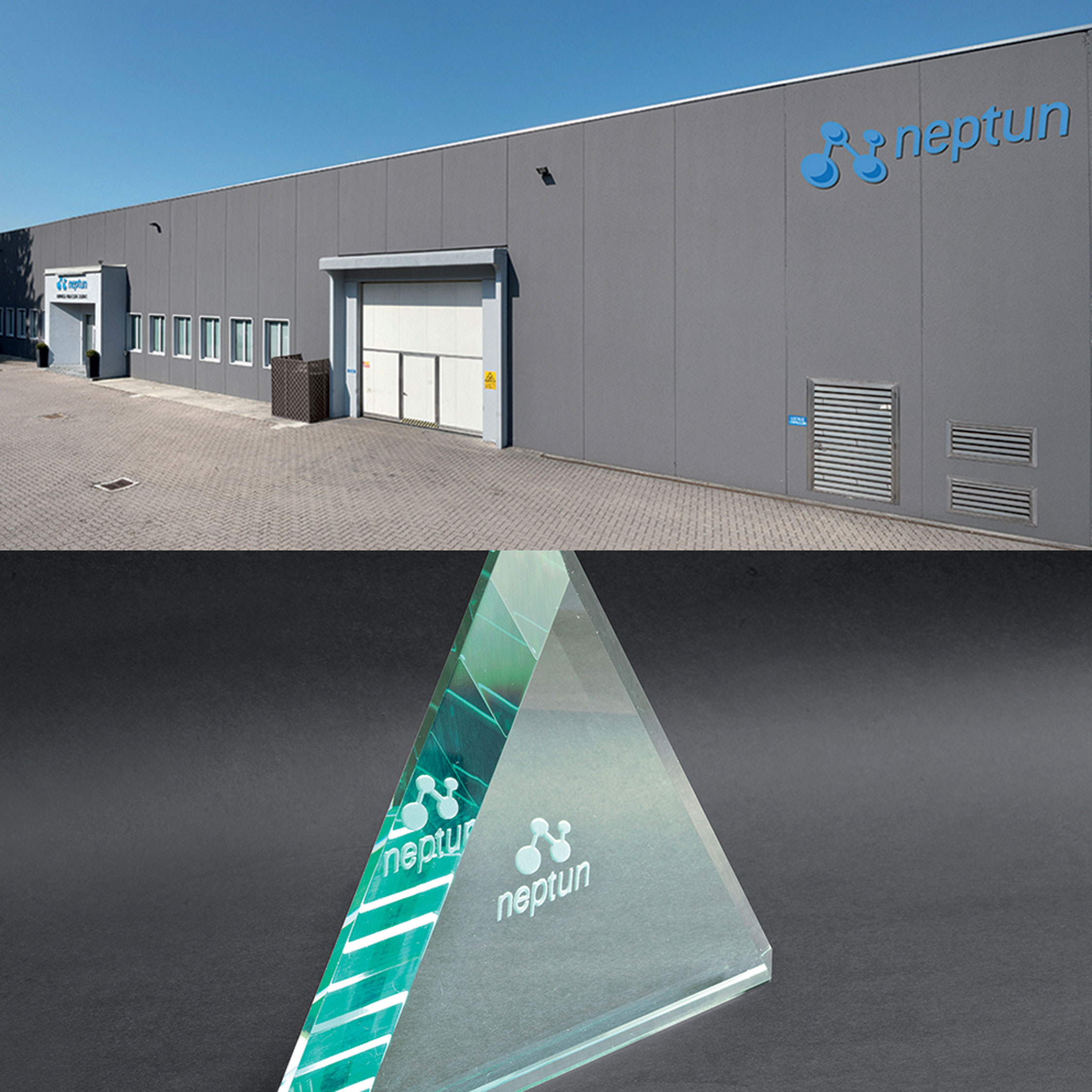

Neptun, 2008 yılı sonunda Stefano Bavelloni tarafından kuruldu ve ürettiği cam işleme çözümleri ile kısa sürede önemli üreticiler arasına girdi.

2011 yılında ortak olarak katılan Simona Bavelloni ve Matteo Rolla, şirketin hızla büyümesine katkıda bulundular. Ayrıca Dino Bavelloni ve Franco Bavelloni'nin onlarca yıllık tecrübelerini aktardıkları danışmanlıkları bu süreçte Neptun’ün gücüne güç kattı.

Neptun, kanıtlanmış kalite ve performans isteyen cam işlemeciler için ideal bir ortak konumundadır.

Ürünler

DİKEY DELİK MAKİNESİ

Dikey Delik Makinesi

Otomatik dikey delik makinesi ile camın istediğiniz yerinde herhangi bir siyah leke kalmadan delik açabilirsiniz. Makine tek başına kullanılabileceği gibi daha yüksek üretim seviyeleri için hatta eklenerek de kullanılabilir. Delikler yüksek hassasiyetle açılmaktadır (±0,15mm). Gelişmiş program sistemi sayesinde parametrelerin tanımlanmasından sonra istenirse camı geri çağırmak mümkündür.

YATAY RODAJ MAKİNESİ

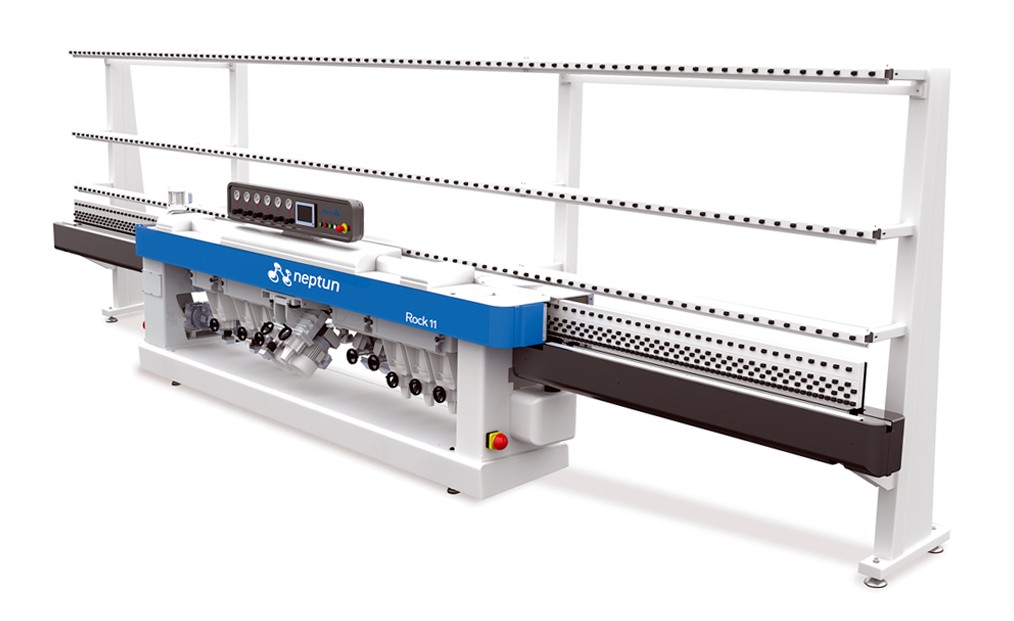

Straight-Line Edger

Yatay Rodaj Makinesi

Yatay rodaj makineleri 3 vardiyada yoğun üretimi destekleyebilen ve yüksek güvenirlikte, düşük bakım maliyetlerini koruyarak uzun yıllar çalışabilen bir yapı ile tasarlanıp, üretilmiştir. Titremeyi engelleyen hassas mekanik aksamlar ve dökme demir kullanımı, Neptun Rodaj serisini aynı sayıda mil kullanan piyasadaki diğer makinelere göre daha yüksek bir işleme hızına ulaştırır. Özel aletlerle 8, 10 mm'ye kadar genişlikte, 45 derecelik eğim gerçekleştirilebilir. Modeller arasında işleme kalitesi açısında fark yoktur. Daha düşük üretim miktarları isteyenler için, yalnızca üretim hızında farklı seçenekler sunulmuştur.

YIKAMA MAKİNELERİ

Yatay Yıkama Makinesi

TORNADO

TORNADO

TORNADO

TORNADO

TORNADO LT

Tornado yatay yıkama makineleri yüksek hızda çalışırken en üst kalite yıkama, temizleme ve kurutmanın talep edildiği endüstriyel kullanımlar için en uygun makinedir. Özel otomasyon ile tasarlanan sistem, su kalitesi ve enerji tüketimi için otomatik kontrol sağlar.

Geniş seçenek yelpazesi ile farklı üretim aşamalarında ihtiyaç duyulan yıkamalar için idealdir. 1300mm’den 3.000mm’e kadar ebatlar mevcuttur.

Dikey Yıkama Makinesi

LV TOP SUPERINOX

IG Line

LV TOP

Superinox

Dikey yıkama makinesi Superinox, cam yıkama ve kurutma performansı ile endüstride yıkama konusunda ihtiyaç duyulan tüm özellikleri sahiptir. Yüksek kalınlıkta, paslanmaz çelikten üretilen çok sağlam bir yapısı vardır. Suyla temas eden tüm parçalar (kurutma bölümü dahil) paslanmaz çelikten ve korozyon önleyici malzemelerden yapılmıştır. Tüm kumanda parçaları makinenin üst kısmında, suyla temas etmeyecek bölümlerde yer alır.

Superinox, otomatik low-e tespit sistemi ile bu tip camlar için de uygundur. Kalınlık ayarlaması otomatiktir. Dokunmatik ekranlı PLC kontrol sistemi ile hız, kalınlık ve cam çeşidi kolayca yönetilebilir.

Dikey yıkama makinemize çeşitli yaratıcı çözümler eklenebilir. Örneğin patentli Ecosave sistemi eklenerek enerji tüketimi %60 azaltılabilir. Yada A-Qual sistemi ile su saflık seviyesi otomatik olarak kontrol edilebilir ve yönetilebilir.

Superinox, Neptun yada başka firma tarafından üretilmiş IG üretim hattına, dikey delik makinesine entegre edilebilir. Ayrıca köşe kırım modülü eklenerek otomatik köşe kesim ile de entegre etmek mümkündür.

BROCHURE 1

BROCHURE 2

BROCHURE 3

BROCHURE 4

WEB

Glass Processing Machines

Neptun Srl was founded by Stefano Bavelloni in late 2008, as a manufacturer of machines and equipment for flat glass cleaning. It has established itself in a short time among the key players in creating solutions for glass processing. Simona Bavelloni and Matteo Rolla, who joined as partners in 2011, have contributed to the fast growth of the company.

Neptun Srl also counts on the prestigious consultancy of Messrs. Dino Bavelloni and Franco Bavelloni, well known thanks to their important expertise, built up over decades of experience and success.

The actual product range includes vertical and horizontal washing machines, straight-line edgers and mitering machines, IG lines, vertical working centers for drilling, milling and seaming. Neptun stands as the ideal partner for all glass industry companies who require proven quality, performance and reliability.

Products

VERTICAL WORKING CENTERS

Quickdrill

Vertical Working Centers

Automatic vertical CNC drilling machine with manual tools exchange for fast and precise execution of drilling holes and countersinks. The drilling holes can be made on the entire area of the glass sheet without any black zone. Quickdrill can be integrated with the module Quickmill, to create line allowing to execute, after the drilling operations, also milling and edging for the creation of notches.

High precision in the positioning of the holes up to ±0,15mm. Powerful function of nested programs, allowing their recall and repeat “n” times after definition of the parameters.

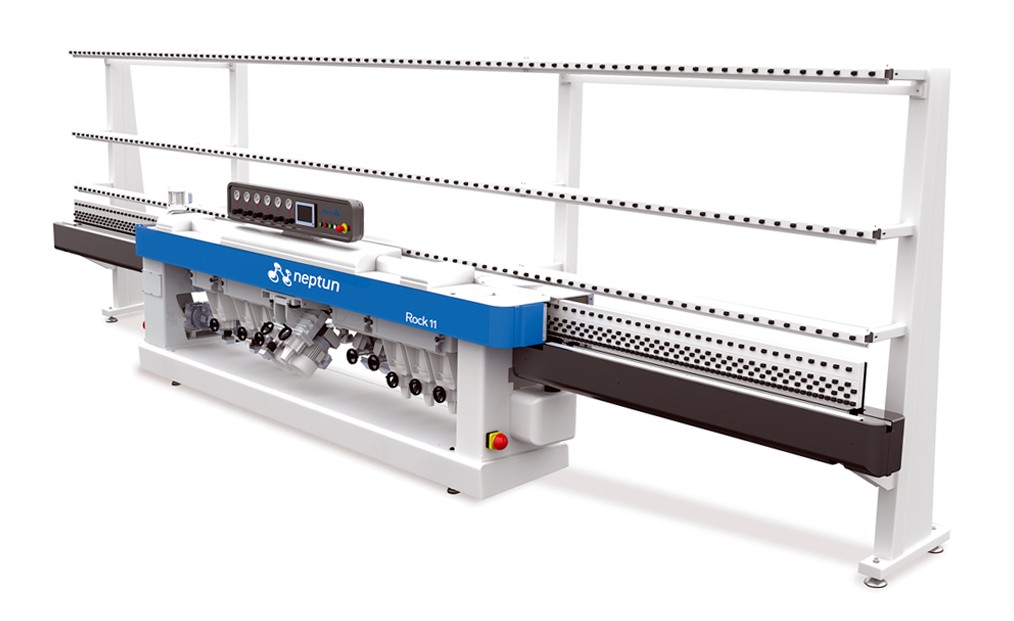

Straight-Line Edger

Straight-Line Edger

Thanks to the sturdiest structure on the market, Rock stands out for its extraordinary production speed combined with high precision and processing quality. Rock is built to last for years, even in heavy duty working conditions. The structure is fully made of cast iron and high thickness steel processed with innovative technological solutions aimed to maintain precision and reduce mechanical wear and thus maintenance costs. This also leads to an unprecedented low noise level. Many advanced and patented solutions, such as the conveyor pad in double material and the ETS squaring system, are the result of a consolidated know-how and heavy investment in R&D. These features grant Rock a highly innovative character, extending the straight-line edger use to never before considered applications. The Rock range encompasses the best edging tradition while making its mark in glass processing history to create new benchmarks.

WASHING MACHINES

Horizontal Washing Machines

Tornado HP

TORNADO

Tornado HP is the most suitable horizontal washer for industrial processing, where the highest reliability in terms of washing and drying quality is requested, when working at high production speed. Conceived with a high level of automation, it can be completed with an automatic control system for water quality and energy consumption. The wide range of options make it ideal for several production requirements: glass edging plants, screen-printing and lamination lines and production of solar panels. Available for dimensions from 1300 to 3300mm.

Horizontal Washing Machines

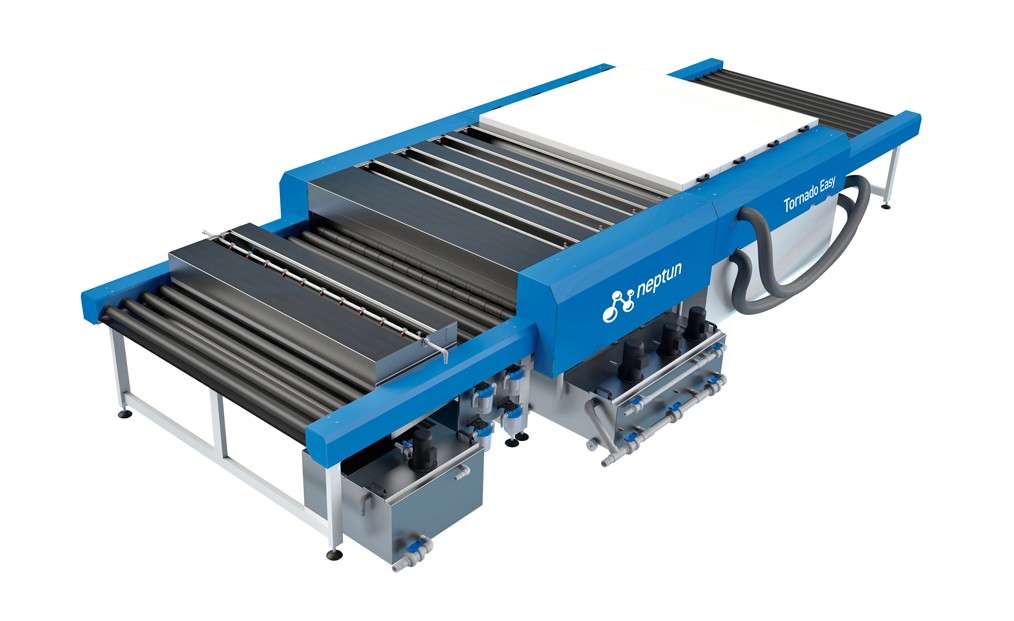

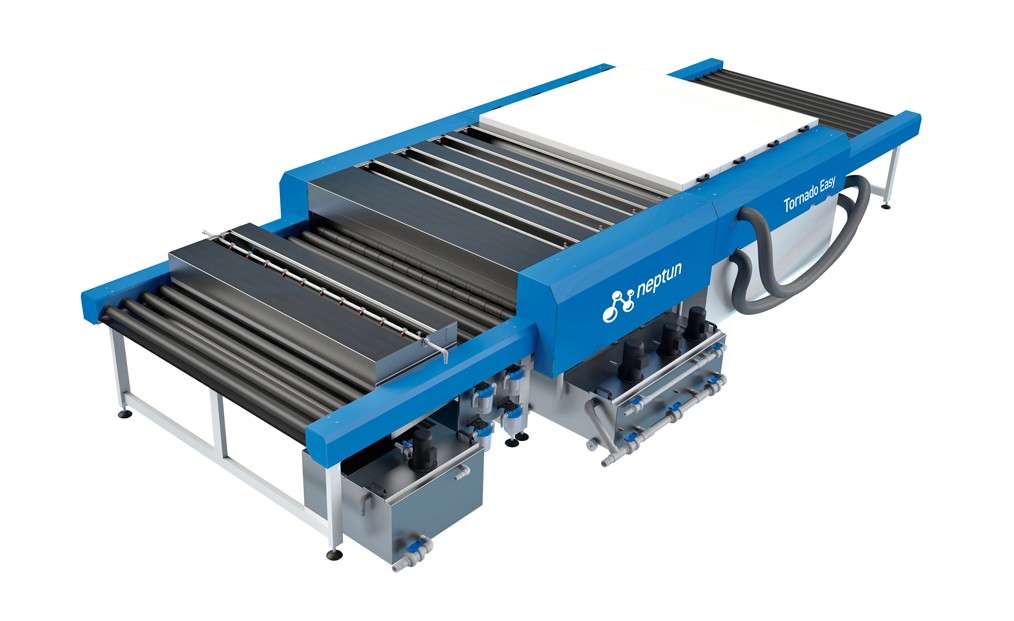

Tornado Easy

Tornado Easy

Tornado Easy is the line of horizontal washing machines by Neptun; it is designed as a basic version of the Tornado HP and maintains its basic features; it is intended for situations where cost effectiveness is critical while performance requirements are not excessively high. A reliable machine for accurate washing of 1300 to 2600mm glasses, especially designed as for a stand-alone or in-line use for factories with limited investment budgets.

Horizontal Washing Machines

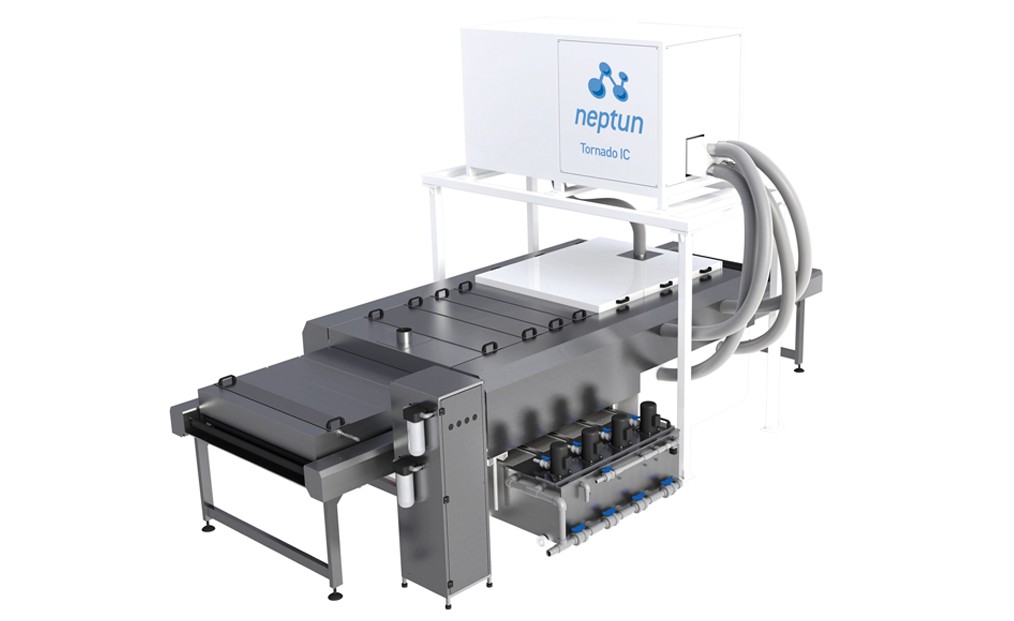

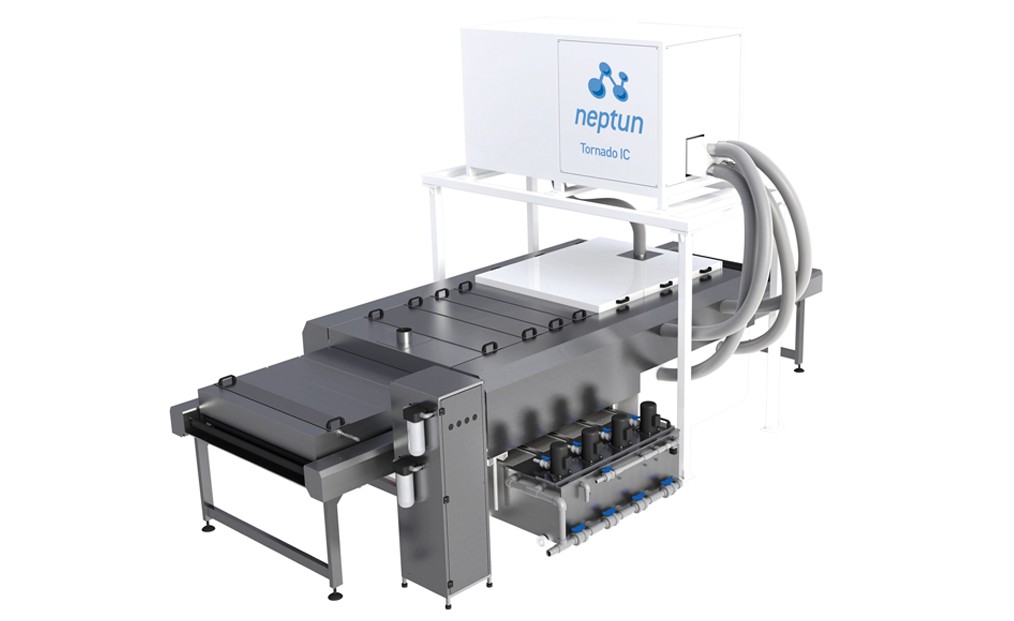

Tornado IC

Tornado IC

Tornado IC is a horizontal washing machine designed to meet the most extreme requirements in terms of glass cleaning. Tornado IC was developed for the semiconductor industry, for the cleaning of substrates prior to the deposit of TCO at an intermediate stage of production of solar panels and in all situations where a decontamination level compatible with ISO Class 4 clean room is needed (Class 10 FED STD 209E). Available for dimensions from 1300 to 2000mm.

Horizontal Washing Machines

Tornado LT

Tornado LT

Tornado LT is the most suitable horizontal washer for industrial processing, where the highest reliability in terms of washing and drying quality is requested, when working on thin glass sheets. Conceived with a superior degree of accuracy, it allows a precise adjustment of brushes and air flow, in order to guarantee the correct processing of glass sheets with thickness as little as 0,6mm. Available for dimensions from 1300 to 1600mm.

Vertical Washing Machines

SUPERINOX

Superinox

Top performance

The vertical washing machine Superinox guarantees the best performances for washing and drying glass available on the market. It is completely made with a solid supporting structure in stainless steel with high thickness. All parts in contact with water, also in the drying area, are made in stainless steel and anticorrosion material. All drives are located on the upper part of the machine, guaranteeing absence of contact with water.

Superinox is ready to process delicate glass, thanks to the automatic detection of low-E glass. The adjustment of the thickness is automatic. The control system through PLC with touch screen allows the management of speed, thickness and types of glass.

Superinox can be equipped with various innovating solutions, which guarantee a superior level of performance, such as the patented system Ecosave, which reduces the energy consumption up to 60% and the system A-Qual, which allows the automatic management and control of the level of purity of the water. Superinox can be integrated with IG production lines and vertical working centers manufactured by Neptun or other manufacturers. Superinox can also be integrated with the CornerCut module, in order to combine automatic corner cutting in the washing process.

Vertical Washing Machines

LV TOP

LV TOP

The most reliable entry level washer.

The washing machine LV Top is an easy-to-use machine, which from all points of view incorporates the main benefits of the superior Superinox range. Reliable and longlasting, accurately engineered, only needing minimal maintenance, conceived for those who need an efficient washing and drying. LV TOP is meant for the glass processing companies of all sizes who do not require complex automation levels. LV TOP is made with a solid supporting structure in stainless steel, both for the washing and the drying section. The doors in tempered glass allow an easy inspection of the working cycle, and increase the sound insulation. All parts in contact with water are made in stainless steel or anticorrosion materials. The outlet module is complete with a lightning panel for visual control of the cleaning and a security sensor that stops the conveyor and avoids the glass running off the end of the conveyer. The control panel is located in an ergonomic position and, thanks to several features, the entire maintenance of the machine is simplified.

LV Top can be integrated, with appropriate modifications, in the IG lines and with the vertical working centers manufactured by Neptun. LV TOP can be integrated also with the module CornerCut, to include automatic corner cutting in the washing phase.

Vertical Washing Machines

IG Lines

IG Lines

The washing machines Superinox and LV Top can be combined with the coupling press AP300 in order to create insulating glass production lines, which can produce up to 400 panels/day, with workable dimensions up to 2600x3700mm. AP 300 is a flat press with numerical control, driven by brushless motors and ball screws for fast and precise cycles, offering high level performances. The press can be opened up to 500mm in order to facilitate maintenance. AP allows the management of structural coupling up to 100mm in X and Y, which can be set through the touch screen. The positioning module, with independent motorization, allows the coupling of double and triple panels.

BROCHURE 1

BROCHURE 2

BROCHURE 3

BROCHURE 4

WEB