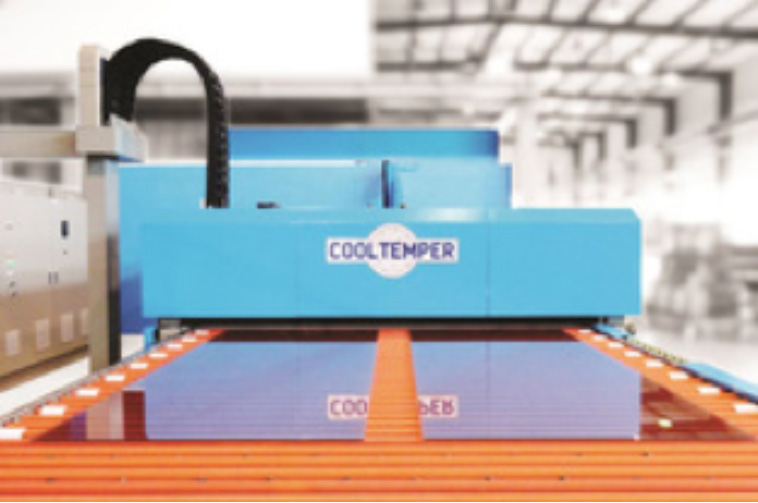

COOLTEMPER

Founded in 1976, COOLTEMPER is synonymous with quality, high technology, and glass tempering equipment. As a major supplier to the world's leading glass companies, today it is a worldwide recognized and trusted strategic partner.

Manufacturing from three factories, COOLTEMPER has a total of 24,000 m2 of capacity with 200 highly skilled technicians, engineers and office staffs. As an ISO 9001-2000 certified manufacturer supplying to over 35 different countries, it has also to comply with CE, UL, ASME & CSA standards.

With a company policy of constant reinvestment in products and new technology, COOLTEMPER aims to keep four to five years ahead of its competitors. For this reason we are internationally renowned for supplying reliable and energy efficient products. Using quality components on the machines is also very important as no company can make all the parts. Our parts suppliers are market leaders with the best technology in their area of expertise.

Machineries

Blade

Thin Glass Tempering Furnaces

Blade

Blade is supplied to manufacture fully tempered 1.8 & 2mm (5/64”) glass products in the photovoltaic and white goods industry to EN 12150 standards. Glass stress levels of 120 mpa can be achieved. FireJet + full convection technology is used in the oven section and Cooltemper’s unique quenching system guarantee industry leading glass surface and optical quality.

Key features:

- Special quench design for thin glass tempering.

- Top & bottom full re-circulated, block zonal, forced air delivery system.

- Energy efficient insulation, heaters, quenching systems, drives and controls.

- Block matrix heaters using energy saving, pulse power input modules.

- Windows based inter phase controls.

- Internet modem connection.

Blade models:

| Blade Ultra™ - Double chamber | |

| Maximum glass sheet size: | 1000 x 1650mm (40” x 65”) |

| Glass thickness: | 1.8~8mm (5/64” – 5/16”) |

| Production speed: | Clear float glass 2mm (5/64”): 45 sec/load, 80 loads/hr. |

| Blade Trio™ - Triple chamber | |

| Maximum glass sheet size: | 1000 x 1650mm (40” x 65”) |

| Glass thickness: | 1.8~8mm (5/64” – 5/16”) |

| Production speed: | Clear float glass 2mm (5/64”): 36 sec/load, 100 loads/hr. |

Minimo

Mini Horizontal Tempering Furnace

Minimo

Mini Horizontal Tempering Furnace

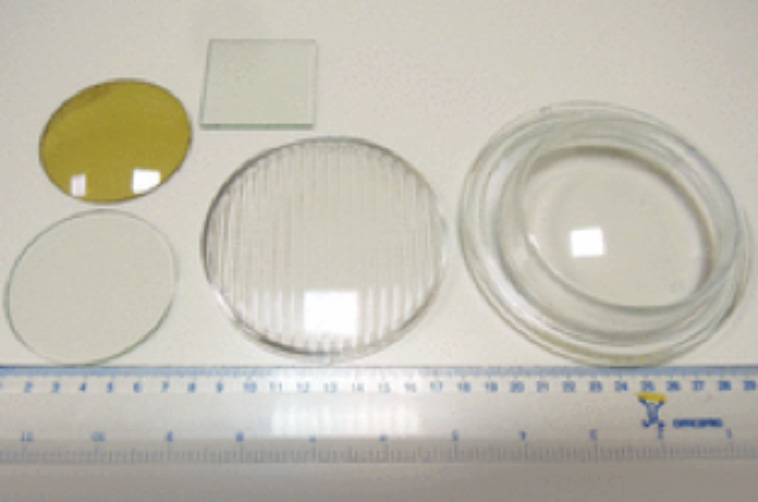

Minimo™ was designed specifically for tempering tight tolerance/specification, small glass sizes requiring an extremely good optical surface quality. The Minimo is typically used in test labs and coating line testing facilities as well as pilot production lines. Products to be tempered would include pressure gauges, viewing glasses and touch screens.

Key features:

- Top and bottom, aspirated convection system with program specific pressure profiling.

- Tight roller pitch enabling small glass sizes to be tempered.

- Energy efficient insulation, heaters, quenching systems, drives and controls.

- Space saving single quench/cooling fan design.

- Inverter driven quench/cooling fan.

- Automatic quench air balance adjustment system.

- Independent top & bottom quench area nozzle adjustment.

- Automatic, multi position, self-tracking glass load system.

- Internet modem connection.

Furnace sizes/details:

| Glass width: | 0.6M~0.8M (23” - 32”) (Standard and Customized Sizes Available) |

| Glass length: | Maximum 1~1.2M (40” - 47”) |

| Glass thickness: | 2.8mm~19mm (1/8” – ¾”) (with 25mm 1” option) |

| Minimum glass sizes: | 50 x 50mm (2” x 2”) |

Firejet+

Tempering Furnace with Top & Bottom Re-circulated Convection Blowers

Firejet+

FireJet +™ is capable of tempering all current glass products from clear float to triple silver coatings with superior cycle times and finished glass quality. The system utilizes fans to fully re-circulated hot air, both top and bottom, inside the oven area.

Key features:

- Top & bottom full re-circulated, block zonal, forced air delivery system.

- Energy efficient insulation, heaters, quenching systems, drives and controls.

- Block matrix heaters using energy saving, pulse power input modules.

- Space saving single quench/cooling fan design.

- Inverter driven quench/cooling fan.

- Automatic quench air balance adjustment system.

- Independent top & bottom quench area nozzle adjustment.

- Automatic, multi position, self-tracking glass load system.

- Windows based interphase controls.

- Internet modem connection.

- Heat strength program 3-12mm thick glass.

Furnace sizes/details:

| Glass width: | 1.2M~2.8M (47” - 110”) (Standard and Customized Sizes Available) |

| Glass length: | Maximum 8M (315”) |

| Glass thickness: | 2.8mm~19mm (1/8” - ¾”) (with 25mm 1” option) |

Firejet

Tempering Furnace with Top Re-circulated & Bottom High Speed Blowers

Firejet

FireJet™ is capable of tempering all current glass products from clear float to triple silver coatings. The system utilizes zonal fans in the top of the oven to fully re-circulated hot air, and energy efficient high speed convection fan in the bottom of the oven to assist the heating of the glass.

Key features:

- Hybrid convection combining a full re-circulated, block zonal, forced air delivery system in the top of the furnace and a high speed air blower block zonal convection system in the bottom of the furnace.

- Energy efficient insulation, heaters, quenching systems, drives and controls. Block matrix heaters using energy saving, pulse power input modules.

- Space saving single quench/cooling fan design.

- Inverter driven quench/cooling fan.

- Automatic quench air balance adjustment system.

- Independent top & bottom quench area nozzle adjustment.

- Automatic, multi position, self-tracking glass load system.

- Windows based interphase controls.

- Internet modem connection.

- Heat strength program 3-12mm thick glass.

Furnace sizes/details:

| Glass width: | 1.2M~3.2M (47” - 130”) (Standard and Customized Sizes Available) |

| Glass length: | Maximum 8M (315”) |

| Glass thickness: | 2.8mm~19mm (1/8” – ¾”) (with 25mm 1” option) |

Ultra Firejet

Double Chambers Tempering Furnace with Top Re-circulation & Bottom High Speed Blowers

Ultra Firejet

The Ultra ranges of furnaces were designed with volume glass production in mind. Using two ovens in combination these furnaces can increase volumes, over an equivalent single chamber model, by as much as 85%.

Ultra models:

Ultra FireJet

Key features:

- Each model has two ovens.

- Energy efficient insulation, heaters, quenching systems, drives and controls.

Furnace sizes/details:

| Glass width: | 1.2 - 3.2 Meters (48” - 126”) |

| Glass length: | Maximum 8 meters (315”) |

| Glass thickness: | 2.8 - 19mm (1/8” - ¾”) (with 25mm 1” option) |

Extreme Firejet

Continuous Tempering Furnace with Top Re-circulated & Bottom High Speed Blowers

Extreme Firejet

Extreme™ is perfect for customers with high volume product demands. All continuous furnaces are made to the customers’ specific production requirements in mind. The extreme furnaces are used for manufacturing photovoltaic & white goods glasses on large production runs. The continuous furnace can be supplied with the Jetstream+, Jetstream RT or FireJet convection design as required dependent upon foot print and product type.

Extreme models:

Extreme FireJet

Hybrid convection combining a full re-circulated, block zonal, forced air delivery system in the top of the furnace and an aspirated block zonal convection system in the bottom of the furnace.

Furnace sizes/details:

| Glass width: | 0.8M~2.2M (31” - 86”) (Standard and Customized Sizes Available) |

| Glass thickness: | 2.8mm~19mm (1/8” – ¾”) (with 25mm 1” option) |

| Production speed: | Depends on production quality: 100~300mm/sec (4” – 12” per sec) |

Jetstream+

Tempering Furnace with Line Heating & Convection Systems

Jetstream+

Jetstream+™offers the user great value with an extremely low running cost and still having the capability of tempering all currently available glasses. It is the perfect all-rounder for both medium and small glass production facilities. Easy to operate with little maintenance required.

Key features:

- Top and bottom, aspirated convection system with program specific pressure profiling.

- Energy efficient insulation, heaters, quenching systems, drives and controls.

- Space saving single quench/cooling fan design.

- Inverter driven quench/cooling fan.

- Automatic quench air balance adjustment system.

- Independent top & bottom quench area nozzle adjustment.

- Automatic, multi position, self-tracking glass load system.

- IMMI control system or optional Windows based interphase controls.

- Internet modem connection.

- Heat strength program 3-12mm thick glass.

Furnace sizes/details:

| Glass width: | 1.2M~3.2M (47” - 130”) (Standard and Customized Sizes Available) |

| Glass length: | Maximum 8M (315”) |

| Glass thickness: | 2.8mm~19mm (1/8” – ¾”) (with 25mm 1” option) |

Jetstream

Tempering Furnace with Basic Line Heating & Convection Systems

Jetstream

Jetstream™ is the entry level tempering furnace for glass processing business. It most suited for clear and hard coated glass. Easy to operate with little maintenance required.

Key features:

- Top and bottom, basic aspirated convection system.

- Energy efficient insulation, heaters, quenching systems, drives and controls.

- Line & auxiliary heaters using energy saving, pulse power input modules.

- Space saving single quench/cooling fan design.

- Inverter driven quench/cooling fan.

- Automatic quench air balance adjustment system.

- Independent top & bottom quench area nozzle adjustment.

- Automatic, multi position, self-tracking glass load system.

- IMMI control system.

- Heat strength program 3-10mm thick glass.

Furnace sizes/details:

| Glass width: | 1.2M~3.2M (47” - 130”) (Standard and Customized Sizes Available) |

| Glass length: | Maximum 8M (315”) |

| Glass thickness: | 2.8mm~19mm (1/8” – ¾”) (with 25mm 1” option) |

Jetstream RT

Tempering Furnace with Matrix Heating & Convection Systems

Jetstream RT

Jetstream RT™is designed to offer superior glass quality, fast cycle times, extremely low running costs and virtually no maintenance. It is the perfect all-rounder for both large and small glass production facilities. Technically advanced in design but simple to use & operate.

Key features:

- Top and bottom, aspirated block zonal convection system with program specific pressure profiling enabling convection area profiling across and down the length of the oven area.

- Energy efficient insulation, heaters, quenching systems, drives and controls.

- Block matrix heaters using energy saving, pulse power input modules.

- Space saving single quench/cooling fan design.

- Inverter driven quench/cooling fan.

- Automatic quench air balance adjustment system.

- Independent top & bottom quench area nozzle adjustment.

- Automatic, multi position, self-tracking glass load system.

- Windows based inter phase controls.

- Internet modem connection.

- Heat strength program 3-12mm thick glass.

Furnace sizes/details:

| Glass width: | 1.2M~3.2M (47” - 130”) (Standard and Customized Sizes Available) |

| Glass length: | Maximum 8M (315”) |

| Glass thickness: | 2.8mm~19mm (1/8” – ¾”) (with 25mm 1” option) |

Ultra RT

Double Chambers Tempering Furnace with Block Matrix Heating & Convection Systems

Ultra RT

The Ultra ranges of furnaces were designed with volume glass production in mind. Using two ovens in combination these furnaces can increase volumes, over an equivalent single chamber model, by as much as 85%.

Ultra models:

Ultra RT

Top and bottom, aspirated block zonal convection system with program specific pressure profiling enabling convection area profiling across and down the length of the oven area.

Key features:

- Each model has two ovens.

- Energy efficient insulation, heaters, quenching systems, drives and controls.

Furnace sizes/details:

| Glass width: | 1.2 - 3.2 Meters (48” - 126”) |

| Glass length: | Maximum 8 meters (315”) |

| Glass thickness: | 2.8 - 19mm (1/8” - ¾”) (with 25mm 1” option) |

Extreme RT

Continuous Tempering Furnace with Block Matrix Heating & Convection Systems

Extreme RT

Extreme™is perfect for customers with high volume product demands. All continuous furnaces are made to the customers’ specific production requirements in mind. The extreme furnaces are used for manufacturing photovoltaic & white goods glasses on large production runs. The continuous furnace can be supplied with the Jetstream+, Jetstream RT or FireJet convection design as required dependent upon foot print and product type.

Extreme models:

Extreme RT

Top and bottom, aspirated block zonal convection system with program specific pressure profiling enabling convection area profiling across and down the length of the oven area.

Furnace sizes/details:

| Glass width: | 0.8M~2.2M (31” - 86”) (Standard and Customized Sizes Available) |

| Glass thickness: | 2.8mm~10mm (1/8”–3/8”) |

| Production speed: | Depends on production quality: 100~300mm/sec (4” – 12” per sec) |

Chemical Tempering

Lumina M

Chemical Tempering Furnace - Multi Chambers

Lumina M

Lumina M is a high volume multi chamber chemical tempering oven used for mass production of thin glass products requiring zero optical distortion. Chemical tempering ovens use the process of iron exchange. By immersing the glass into a Potassium Nitrate chemical bath the sodium irons close to the glass surface are replaced by larger potassium ion atoms. As a result of this chemical exchange the glass has a stronger surface layer. Products using chemically tempered glasses include mobile phones, digital cameras, copy machines & aircraft windscreens.

Key features:

- Pre heating glass tanks.

- Automatic process loading and unloading.

- Reaction time of between 3 – 8 hours (dependent upon stress level required).

- 9 point temperature measurement ±5°C (41°F)

- Heating time: 90~120 minutes.

- Cooling time 90~120 minutes.

- Conforming To EN12337-1:200, ASTM-C1422-99 & JC/T977-2005 standards.

Oven sizes/details:

| Max glass size metric: | 08x20 / 12x12 / 15x20 / 18x20 / 18x30 / 20x25 / 20x30 |

| Max glass sizes Imperial: | 31x78 / 47x47 / 60x78 / 70x78 / 70x120 / 78x98 / 78x120 |

| Post tempering washer tank available upon request. |

Lumina S

Chemical Tempering Furnace - Single Chambers

Lumina S

Lumina S™ is a low production volume chemical tempering furnace suitable for specialty products or product R&D.

Key features:

- Preheater:

- Heating: Room temperature~400℃/450℃ in 90min

- Cooling: 450℃/400℃~100℃ in 90min

- 9 points temperature measurements: +-5℃

- Reaction tank:

- Max temperature: 450℃/500℃

- 9 points temperature measurements: +-2℃

- Post tempering washer tank available.

Oven sizes/details:

| Max glass size metric: | 05x05 / 07x07 / 08x10 |

| Max glass sizes Imperial: | 20x20 / 27x27 / 31x40 |

CIC

Production Reporting System

CIC

- CIC_OM: Glass Temperature Online Monitor

- Fast and simple recipe optimization

- CIC_PR: Production Reporting

- Improvement of productivity and production efficiency

- CIC_QR: Quality Reporting

- For certification and complaint management

- CIC_ER: Energy Reporting

- For cost calculation, pricing and energy saving

- CIC_LC: Automatic Louver Control

- For stable and constant production quality

- CIC_BR: Data Backup & Restore

- To protect important production data

Curvjet

Horizontal Glass Bending Oven

Curvjet

Curvjet™ glass bending oven is designed to manufacture annealed glass bends for a variety of applications. The system is used to bend architectural facade glass, curved glass display case, interior partition, glass furniture and automotive windshield. The bent glass can be laminated to make a safety glass post bending.

Key features:

- Single, double or triple loading ovens to suit customer volumes.

- Automatic cycle change over between ovens.

- Maximum temperature of 650°C (1200°F)

- Fixed and/or flexible bending moulds for volume or bespoke products.

- Energy efficient heating system.

- Variable/adjustable heater positioning.

- Easy loading/unloading design of the glass products.

Oven sizes/details:

| Max glass size: | 3.3m x 6M (130” X 236”) |

| Heating temperature: | 650℃ (1200°F) |

| Glass thickness: | 2~15mm (5/64” – 5/8”) |

Dryjet+

Glass Print Drying & Firing Furnace

Dryjet+

Dryjet +™ is used for drying, firing glass paint onto the glass surface in the first stage and annealing the glass in the second stage for post processing. Typically a common process for automotive windows.

Key features:

- Energy efficient heating & cooling systems.

- Space saving designs.

Oven sizes/details:

| Max glass width: | 0.9M / 2.1M / 2.5M / 3.0M |

| Max glass widths imperial: | 35” / 82” / 98” / 118” |

| Heating: | 200~600℃ (392 - 1112°F) |

| Speed: | 0.4~5M/min (16” - 197” Min) |

Dryjet

Glass Print Drying Furnace

Dryjet

Dryjet

Dryjet™ is used to dry the ceramic paint onto the glass surface prior to the tempering process. Typically a common process for architectural and interior glass production.

Key features:

- Energy efficient heating & cooling systems.

- Space saving designs.

Oven sizes/details:

| Max glass widths metric: | 0.9M / 2.1M / 2.5M / 3.0M |

| Max glass widths imperial: | 35” / 82” / 98” / 118” |

| Heating: | 200℃ (392°F) |

| Speed: | 0.4~4M/min (16” – 157” Min) |

Soakjet+

Convection Heat Soaking Oven with EVA Laminating System

Soakjet+

Soakjet+

Soakjet +™ is used by architectural glass manufacturers to test and record glass tempering quality in the post tempered glass for nickel sulfide intrusions in compliance to EN 14179-1:2005 (Glass in building Heat-soaked thermally-toughened soda lime silicate safety glass). The Soakjet + is also equipped with EVA laminating system for low volume production of laminated glasses.

Key features:

- Energy efficient heating & cooling systems.

- Supplied with two loading systems, one for each process.

- Space saving designs to suit customer layout requirements.

Oven sizes/details:

| Max glass sizes metric: | 21x36 / 21x40 / 25x40 / 25x30 / 25x45 / 30x60 / 33x80 |

| Max glass sizes Imperial: | 84x144 / 84x157 / 98x120 / 98x177 / 118x236 / 130x315 |

| Heating: | Room temperature ~290℃ in 120 min (554°F in 120 min) |

| Cooling: | 290℃~60℃ in 120 min (554°F - 140°F in 120 min) |

| Temperature evenness: | +- 3~5℃ (± 37.4 - 41°F) |

Washjet

Horizontal Glass Washing Machine

Washjet

Washjet™ is designed with high volume continuous trouble free production in mind using the very best component parts. Washjet is designed so it can also be integrated into a production line situation and controlled through an IPC system, whether it is a laminating line or tempering furnace, eliminating double handling and increasing productivity.

Key features:

- Pre wash system.

- Motorised loading table.

- Six adjustable, anti-cut, long life nylon brushes.

- Three, removable, stainless steel hot water, water tanks with filters.

- Stainless steel and aluminium components inside the system.

- Energy efficient drives, drying fans and control systems.

- Drying fans mounted overhead.

- Motorised unloading table.

- Variable speed from 1 to 3.5M/min (138” min).

- PLC control system.

Sizes/details:

| Speed: | 1M~3.5M/min (40”-138” min) |

| Max glass width metric: | 1.2M / 1.8M / 2.2M |

| Max glass widths imperial: | 47” / 70” / 86” |

Laminjet

Horizontal PVB Laminating System

Laminjet

Laminjet PVB laminate lines and autoclaves are designed to suit the specific customer’s volumes, product type, location and budget constraints. The systems can be used for both EVA and PVB interlayers. Designed and capable of manufacturing, high volume, stock sheets with automatic film application or bespoke shaped, multi-layer products for, lower volume, tempered and annealed glasses.

Key features:

- Automatic stock sheet loading/unloading.

- Incorporated glass washing & drying machine.

- Energy efficient ovens, drives & autoclave systems.

- Automatic film cutting system.

- Clean room and film storage systems.

Sizes/details:

| Max glass size metric: | 15x30 / 25x40 / 25x50 / 25x60 / 30x60 |

| Max glass sizes imperial: | 60x120 / 96x160 / 96x200 / 96x240 / 120x240 |

| Heating: | 100~300℃ (212 - 572°F) |

| Speed: | 0.5~4M/min (20” – 157” min) |

| Min glass thickness: | 3+3mm (1/8”+1/8”) |

| Max glass thickness: | 60mm (2 1/3”) |

| Options: | (auto handling, auto film cutting etc) |

WEB

COOLTEMPER

1976 yılında kurulmuş olan COOLTEMPER günümüzde dünyanın önde gelen cam şirketlerinin ana tedarikçilerinden biridir.

Toplamda 200 tecrübeli teknisyeni, mühendisi ve ofis personeli ile 24.000 m2 kapasiteli 3 fabrikada üretim yapmaktadır. ISO 9001-2000 sertifikalı olarak üretim yapmaktadır.

Ürünlerine ve yeni teknolojiye sürekli yatırım yapma politikası ile rakiplerinin önünde yer alır. Bu nedenle güvenilir ve enerji verimli ürünlerin tedarikinde uluslararası bir üne sahiptir. Makinelerde en üst kaliteli parçaları kullanması COOLTEMPER’i diğer şirketlerden ayıran en önemli özelliklerinden biridir. Parça tedarikçileri, alanlarında en iyi teknolojileri kullanan piyasanın önde gelen şirketleridir.

Makineler

Blade

İnce Camlar İçin Temper Fırınları

Blade

Blade 1,8 & 2 mm (5/64”) cam kalınlığına temper yapma ihtiyacı olan fotovoltaik ve beyaz eşya gibi sektörlerde faaliyet gösteren cam işleyiciler için üretilmektedir. Fırın bölümünde FireJet + tam konveksiyon teknolojisi kullanılır ve temper kalitesi ile sektörün talep ettiği en üst görsel kaliteyi garanti eder.

Temel Özellikler:

- İnce camların temperinde özel üretim teknolojisi

- Üst & alt tam devirli, basınçlı hava dağıtım sistemi

- Enerji verimi sağlayan yalıtım sistemi, özel ısıtıcılar, söndürme sistemleri, sürücüler ve kontrol sistemleri

- İnternet modem bağlantısı

Blade modelleri:

| Blade Ultra™ - Çift Bölme | |

| Maksimum cam plaka ölçüsü: | 1000 x 1650mm (40” x 65”) |

| Cam kalınlığı: | 1.8~8mm (5/64” – 5/16”) |

| Üretim hızı: | Düz cam 2mm (5/64”): 45 saniye/yükleme, 80 yükleme/saat. |

| Blade Trio™ - Üç Bölmeli | |

| Maksimum cam plaka ölçüsü: | 1000 x 1650mm (40” x 65”) |

| Cam kalınlığı: | 1.8~8mm (5/64” – 5/16”) |

| Üretim hızı: | Düz cam 2mm (5/64”): 36 saniye/yükleme, 100 yükleme/saat. |

Minimo

Mini Yatay Temper Fırını

Minimo

Mini Horizontal Tempering Furnace

Minimo™ küçük cam ölçülerinde kusursuz görsel yüzey kalitesi gerektiren durumlar için dizayn edilmiştir. Minimo genellikle test laboratuvarlarında, kaplama hattı testi yapan kurumlarda ya da pilot üretim yapılan yerlerde kullanılır. Temperlediği ürünler arasında basınç göstergeleri, gözlük camları ve dokunmatik ekranlar bulunur.

Temel Özellikler:

- Üstte ve altta özel basınçlı konveksiyon sistemi

- Küçük cam boyutlarının temperlenmesini sağlayan sık merdane aralığı

- Enerji verimi sağlayan yalıtım sistemi, özel ısıtıcılar, söndürme sistemleri, sürücüler ve kontrol sistemleri

- Yerden tasarruf sağlayan tekli soğutma fan tasarımı

- Bağımsız üst ve alt soğutma alanı noozle ayarı

- Otomatik kendi takip sistemi olan cam yükleme sistemi

- İnternet modem bağlantısı

Fırın Ölçüleri/Detayları:

| Cam Genişliği: | 0.6M~0.8M (23” - 32”) (Standart ve özelleştirilmiş Ölçüler Mevcut) |

| Cam Uzunluğu: | Maksimum 1~1.2M (40” - 47”) |

| Cam Kalınlığı: | 2.8mm~19mm (1/8” – ¾”) (25mm 1” opsiyonu ile) |

| Minimum cam ölçüsü: | 50 x 50mm (2” x 2”) |

Firejet+

Üst ve Alt Devirli, Konveksiyon Fanlı Temper Fırını

Firejet+

FireJet +™ düz camlar ve üç katlı gümüş kaplamaya kadar mevcut tüm cam ürünlerini hızlı ve mükemmel cam kalitesi ile temperleyebilir. Sistem, fırın alanı içinde hem üstte hem de altta sıcak hava sirkülasyonunu kusursuz sağlamak için özel fanlar kullanır.

Temel Özellikler:

- Üst & alt tam devirli, basınçlı hava dağıtım sistemi

- Enerji verimi sağlayan yalıtım sistemi, özel ısıtıcılar, söndürme sistemleri, sürücüler ve kontrol sistemleri

- Alandan tasarruf sağlayan tekli soğutma fanı tasarımı

- Otomatik kendi takip sistemi olan cam yükleme sistemi

- Windows tabanlı ara faz kontrolleri

- İnternet modem bağlantısı

- 3-12 mm kalınlığında camlar için sıcaklığa dayanıklılık programı

Fırın Ölçüleri/Detayları

| Cam Genişliği: | 1.2M~2.8M (47” - 110”) (Standart ve özelleştirilmiş Ölçüler Mevcut) |

| Cam Uzunluğu: | Maksimum 8M (315”) |

| Cam Kalınlığı: | 2.8mm~19mm (1/8” - ¾”) (25mm 1” opsiyonu ile) |

Firejet

Üstten hava sirkülasyonlu, alttan yüksek hızda üflemeli Temper Fırını

Firejet

FireJet™ mevcut tüm düz cam ve kaplamalı cam ürünlerini hızlı şarj sürelerinde, mükemmel cam kalitesi ile temperleyebilir. Sistem, fırının üst kısmında sıcak havanın devir daimi için bölgesel fanları kullanır. Camların ısıtılması için de fırının alt kısımda enerji verimli, yüksek hız konveksiyon fanlarından yararlanır.

Temel Özellikler:

- Fırının üst kısmında tam dolaşımlı, mecburi hava akım sistemli ve ayrılmış bölmeli Hibrit konveksiyon sistemi vardır. Fırının alt bölümünde ise yüksek hızla hava üfleme sistemli ayrılmış bölmeli konveksiyon mevcuttur.

- Enerji verimi sağlayan yalıtım sistemi, özel ısıtıcılar, söndürme sistemleri, sürücüler ve kontrol sistemleri

- Alandan tasarruf sağlayan tekli soğutma fanı tasarımı

- Otomatik söndürücü hava dengesi ayar sistemi

- Bağımsız üst ve alt söndürme alanı noozle ayarı

- Otomatik kendi takip sistemi olan cam yükleme sistemi

- Windows tabanlı ara faz kontrolleri

- İnternet modem bağlantısı

- 3-12 mm. kalınlığında camlar için sıcaklığa dayanıklılık programı

Fırın Ölçüleri/Detayları:

| Cam Genişliği: | 1.2M~3.2M (47” - 130”) (Standart ve özelleştirilmiş Ölçüler Mevcut) |

| Cam Uzunluğu: | Maksimum 8M (315”) |

| Cam Kalınlığı: | 2.8mm~19mm (1/8” - ¾”) (25mm 1” opsiyonu ile) |

WEB