Projects and Processed Glass

In addition to facades, the increasing usage and consumption of glass for interior purposes increased the demand for the right partnership for supply of processed glass.

We are providing solutions to supply processed glass as per the requirements of the project with our experienced team.

We ensure to supply the products meeting the demand at competitive price and top quality levels by quick service, so that to satisfy the customers.

Basic glass processes for projects:

- Cutting

- Edge Processing – Drilling (Horizontal-Vertical)

- Surface Processing - Printing (Silk Screen, Roller, Digital)

- Tempering (Full, Semi)

- Heat Soak

- Lamination (PVB, Eva, DG-41, Vacum, Sentry Glass, Vanceva Colors, Magic film)

- IGU – Double/Triple Glazing

- Bonding

Specifications and the Capabilities

Specifications and the Capabilities

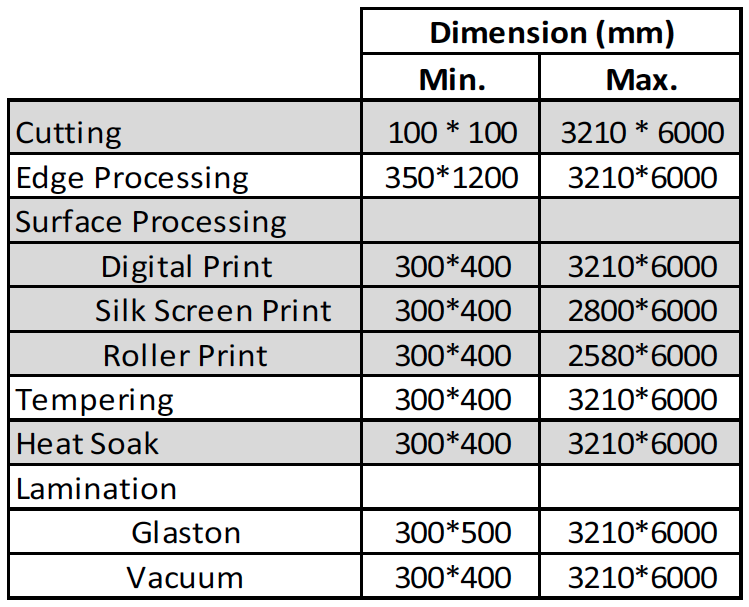

Processing Details

Edge Processing and Drilling (Horizontal – Vertical)

Grinding

It is the process of taking the sharpness and shaping the glass edges. Grinding the edges with 90° and 45° slope is flat grinding, grinding the edges like pen-point is C grinding.

Bevelling

It is the grinding process of glass in 90° angle on glass edge and desirable angle on front of the glass.

Drilling

It is the process of drilling the glass in various diameters. Diameters of holes generally should not be less than the thickness of the glass.

Surface Processing –Printing (Silk Screen, Roller, Digital)

Full Surface Print

It is the process of painting the glass surface with RAL colors by roller, digital and silk screen coater. Silk screen is the process of painting the glass surface by silkscreen pattern. After printing process, the painted glass has to be tempered.

Safety Glasses

This group comprises fully tempered, laminated and fully tempered -laminated glasses.

Tempered Glasses

Toughening process, involves heating and cooling treatment whereby high compressive stresses are set up at the surfaces with balancing tensile stresses in the center. The process improves the glass strength against impact and thermal stress loads.

Tempered glass is approximately 5 times stronger than annealed glass against impact.

Tempered glass may have "spontaneous breakages" due to nickel sulphide particles inside float glass. To reduce the risk of "spontaneous breakages" Heat Soak Test is available in our facilities under EN14179 standard. The heat soak test only reduces the risk, it never eliminates.

Laminated Glass

Laminated glass is produced by combining two or more panes of glass with polyvinly butyral (PVB) or ionaplast (Sentry Glas) interlayer(s). When broken laminated glass tends to keep splinters in place therefore minimizing the risks of injury caused by broken glass. Laminated glasses can reduce up to 97% UV radiation, which causes fabrics to fade due to PVB and Ionaplast layers.

Curved Glass

Fully tempered and fully tempered laminated glasses. Curved laminated glass is produced with the vacuum technique.

Production of curved glass: The radius are changeable in accordance with glass thickness.

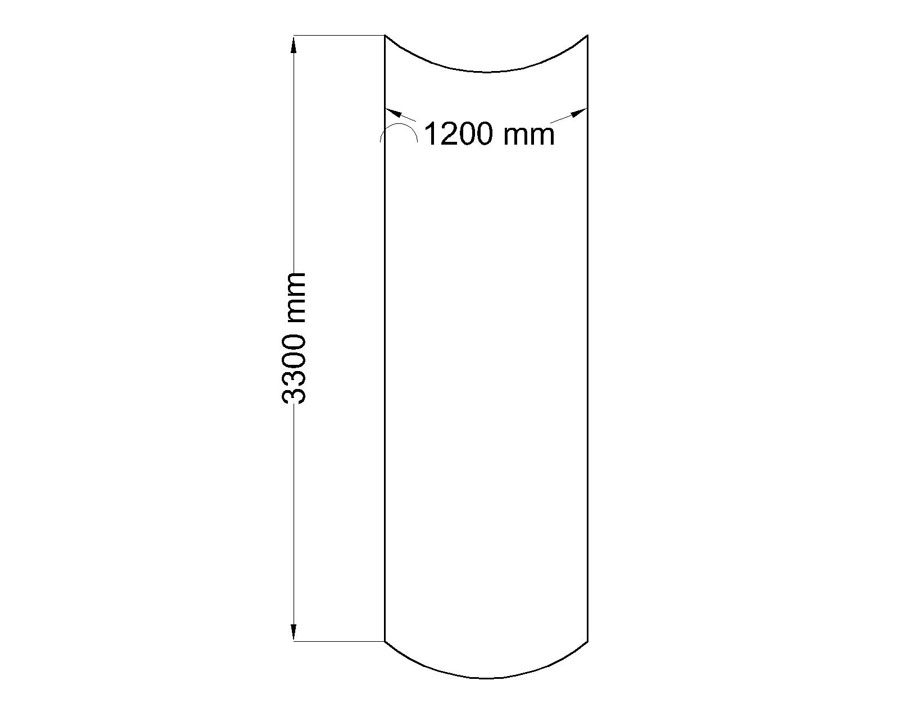

3300hx1200 mm Bending:

3300hx1200 mm Bending

Maximum glass size: 3.300 (height) x 1.200 mm (bending)

Minimum glass size: 300 (height) x450 mm (bending)

Min Bending Radius (r) for:

5-6 mm: 550 mm(for hole and CNC processes, approval is necessary.)

4-8 mm: 1.000 mm (for 4 mm single plate should be less than 2,5 m2.)

10 mm: 1.200 mm

15 mm: 1.500 mm (approval is necessary)

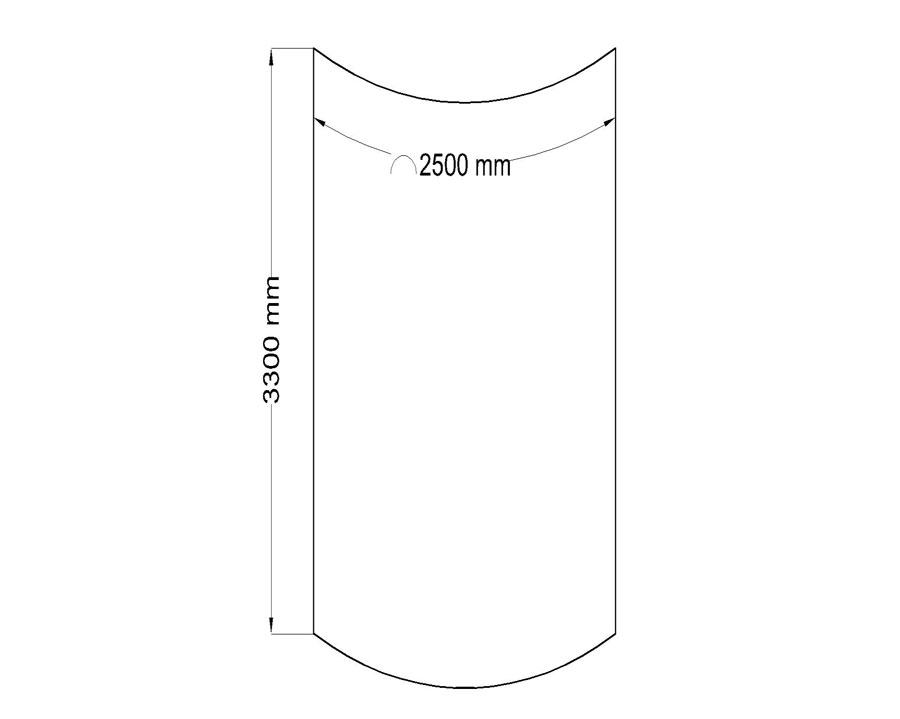

3300hx2500 mm Bending:

3300hx2500 mm Bending

Maximum glass size: 3.300 (height) x 2.500 mm (bending)

Minimum glass size: 300 (height) x450 mm (bending)

Min Bending Radius (r) for:

5-6-8 mm: 1.000 mm(for hole and CNC processes, approval is necessary.)

10 mm: 1.000 mm(approval is necessary.)

12 mm: 1.500 mm

15 mm: 1.800 mm

19 mm: 2.000 mm

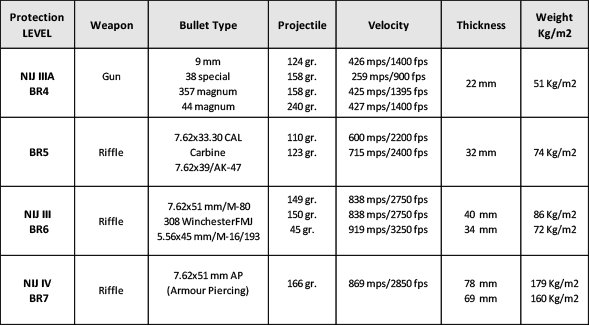

Bullet Proof Glasses

Bullet-proof glasses protects individuals against firearm attacks: Bullet proof glass is a multi- laminated assembly, contains polycarbonate and glass plates. If it is required, layers of multi-laminated assembly can be tempered. The various classes according to EN1063 are determined by the type of weapon.

Installation:

- Bullet-proof glasses generally dissymmetrical and only bullet-proof if positioned facing the correct direction.

- When assembling a laminated bullet-proof glass in insulating glazing, the laminated glass should be positioned on the side opposite the potential impact.

Test Certificated Products:

Test Certificated Products

Fire Proof Glasses

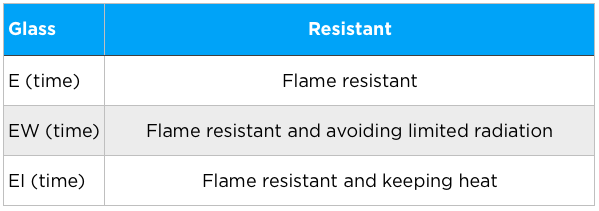

There is three type marking for fire proof glass classification.

- E = Flame resistant, product keeps its integrity.

- W = Limited radiation, avoids radiation within its time.

- I = Isolation, not to transfer the heat to another side within its time.

The available periods are 30, 45, 60, 90, 120 minutes.

Fire Proof Glass Classification

The thickness of fire proof glasses varies according to exterior or interior applications. If a fire proof glass is used for double glazing unit, it is obligatory that fire proof glass has to replaced against possible fire danger.

Fire Proof Glass Classification

Sound Control Glasses

Sound control glass can be produced by using "Acoustic PVB" which is 1.14 mm in thickness or 0.76 mm in lamination.

It is possible to create 3-4 times of difference between "exterior" and "interior" noise levels by sound control glasses. It is possible to create combinations which have 50 dB (decibel) noise isolation.

Insulating Glass Units

The IG unit is produced by combining two or more panes of glass. The glass panes are separated by a spacer. The space between the two panes of glass is filled with air or gas which will provide proper dry air or insulation compatible with ambient pressure.

Glass Types For Processing

Clear/Low Iron Glasses

Depending on the stated conditions of the project all type of clear/low iron/mid iron glasses of worldwide well known glass manufacturers can be processed.

Heat and Solar Control Glasses

Depending on the stated conditions of the project all type of heat and solar control coated glasses produced by worldwide well known glass manufacturers can be processed.

Tinted Glasses

The body-tinted glasses having different colors, like blue, bronze, green, grey are called sun control glasses. Tinted solar control glass is subjected to thermal breakage risks. In order to avoid thermal breakage risks, toughening or heat strengthening is recommended. When laminating tinted glass, all panes of the laminated glass should be either toughened or heat strengthened in order to avoid thermal breakage risks.

Reflective Glasses

Glasses with a hard A-type pyrolytic coating according to EN 1096-1 is called reflective glasses which control the sun lights. Different colors, like blue, bronze, clear, green, grey are available. Reflective solar control glass is subjected to thermal breakage risks. In order to avoid thermal breakage risks, toughening or heat strengthening is recommended. When laminating reflective glass, all panes of the laminated glass should be either toughened or heat strengthened in order to avoid thermal breakage risks.